Automation of production processes is a key pillar for modern manufacturing companies. In this context, REG Galbiati Srl emerges as a key player in the industry, specializing in the design and manufacture of customized high-frequency welding machines applied in strategic areas such as automotive, conveyor belts and packaging.

Why is production automation essential?

Production automation is now essential to ensure efficiency, quality and competitiveness. One of the main benefits is increased production efficiency: machines, such as industrial welders, enable faster processes by reducing the margin of error. This allows companies to produce more units in less time while maintaining high quality standards. Another relevant aspect is cost reduction: although the initial investment in advanced technology can be significant, in the long run there are savings through reduced labor, more efficient use of materials and energy, and reduced waste.

Automation also contributes to improved product quality. Modern technologies, such as high-frequency welding, ensure consistent and accurate production, which is essential in industries where reliability is crucial, such as medical and automotive. Finally, adopting automated solutions strengthens market competitiveness. Companies become more flexible and responsive to changes in demand, can introduce innovations faster and respond more accurately to customer needs. Thus, investing in automation means not only optimizing internal processes, but also consolidating one’s position in an increasingly dynamic market.

Why invest in automation now?

Adopting automated solutions means gaining a concrete competitive advantage:

- Faster deliveries: optimized processes to dramatically reduce production time.

- Reduced costs: fewer errors, less waste, maximum efficiency.

- Better, more durable products: consistent quality guaranteed by advanced technologies.

- Real sustainability: lower energy consumption and waste reduction for a greener future.

How can REG Galbiati Srl help automate your production?

REG Galbiati Srl offers advanced solutions for industrial automation through high-frequency welding machines custom-designed for specific sectors.

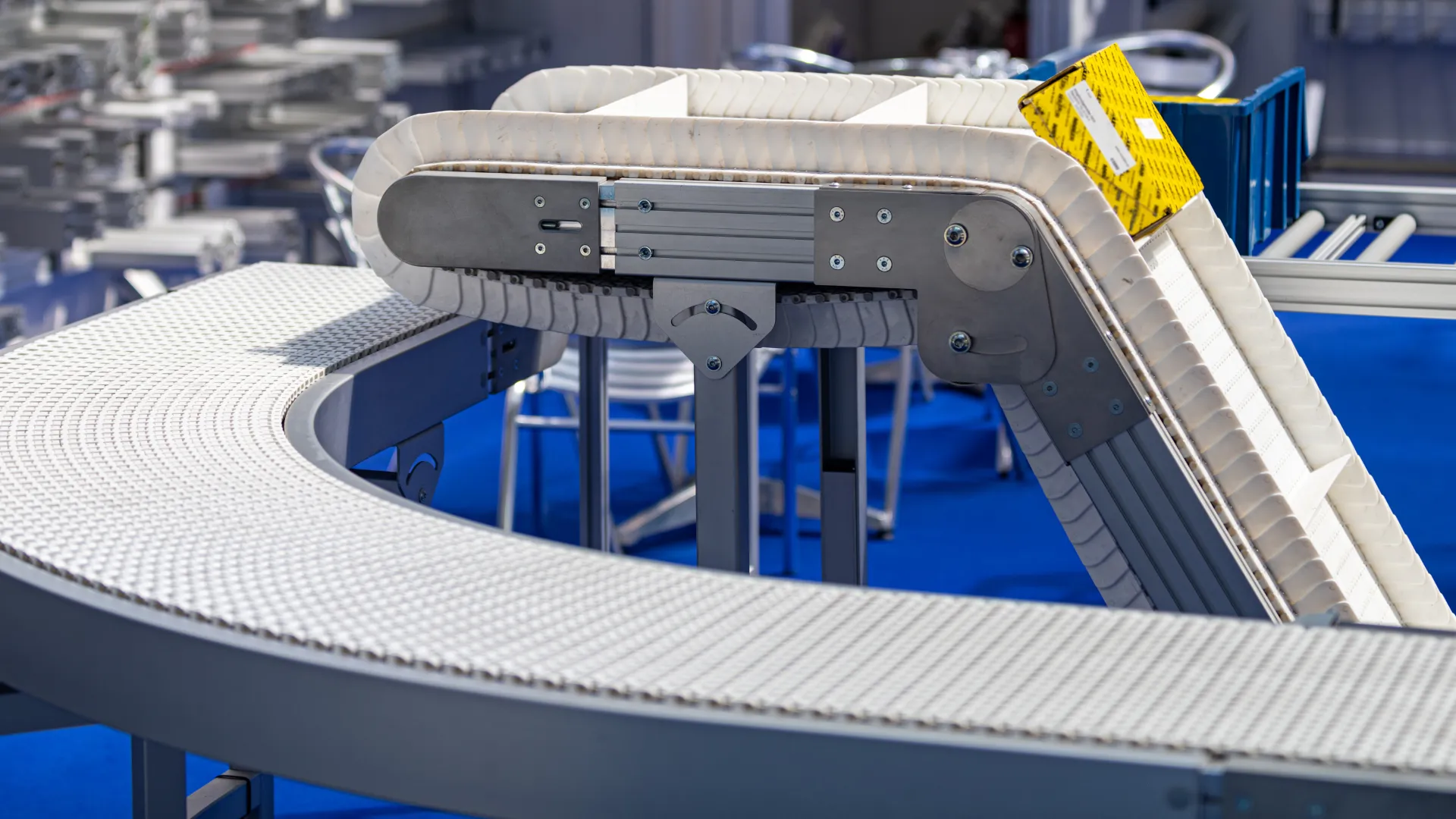

In the automotive industry, their technologies enable automatic quilting of synthetic fabrics for seat covers, ensuring precision and reducing dielectric losses. For conveyor belts, the welders optimize the strength and safety of assemblies while maintaining robust characteristics required by the industry. In packaging, they automate the production of durable, anti-theft packages, combining reliability with aesthetic appeal.

For more information about our solutions and services, please feel free to contact us.