In today’s industrial world, every second lost becomes a cost. That’s why more and more companies are investing in solutions that increase productivity without compromising on quality. One technology that truly makes a difference? High Frequency (HF) Welding.

Why choose high frequency welding?

HF technology is especially valued in industries such as automotive, packaging and conveyor belts, because it allows for:

- Extremely fast welding cycles, even with complex materials

- Strong, durable bonding, with no weak spots

- Consistency and repeatability, ideal for serial production

- Low energy consumption, with high performance

Customization machine is the key

One of the most common problems in production lines is the use of standard machinery that doesn’t align with a company’s specific needs.

At REG Galbiati, each machine is custom-designed based on:

- Material type (PVC, PU, technical fabrics)

- Type of finished product

- Production targets

- Plant layout and available space

- Desired level of automation

Consistent quality means fewer downtimes

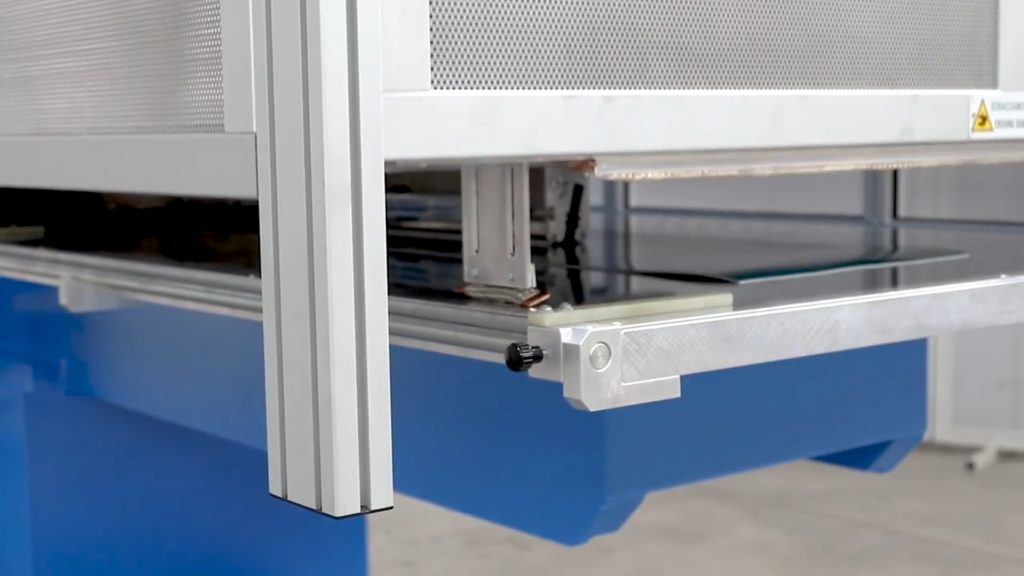

REG Galbiati’s high frequency welders are engineered for long-lasting performance and reliability.

- Longer machine lifespan

- Fewer breakdowns

- Constant quality from day one

This means higher uptime, lower costs, and less stress for your production team.

Take your efficiency to the next level

If you’re evaluating how to optimize your production line or replace an aging welding system, working with a specialized partner can make all the difference.

With over 70 years of experience, REG Galbiati designs and manufactures tailor-made HF welding machines that help industrial clients around the world achieve:

- Higher productivity

- Maximum reliability

- Certified quality standards

- Customized automation

Contact us and discover what a REG Galbiati’s HF welder can do for your production!