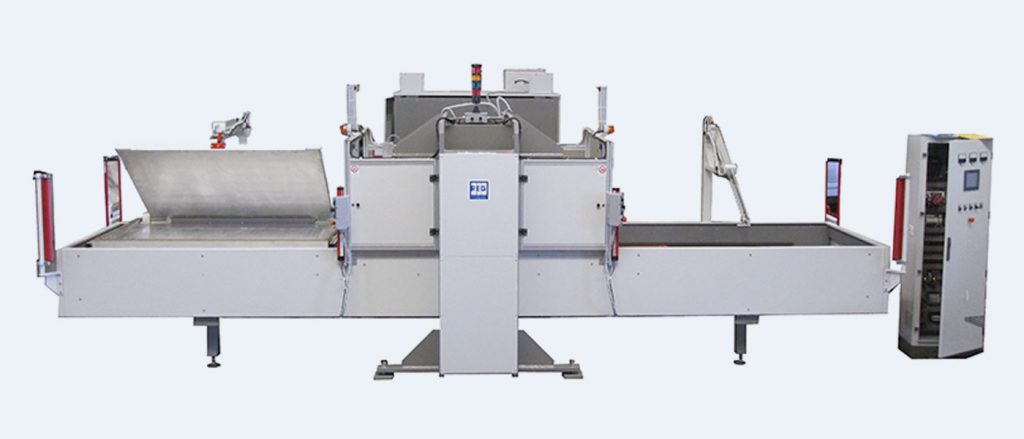

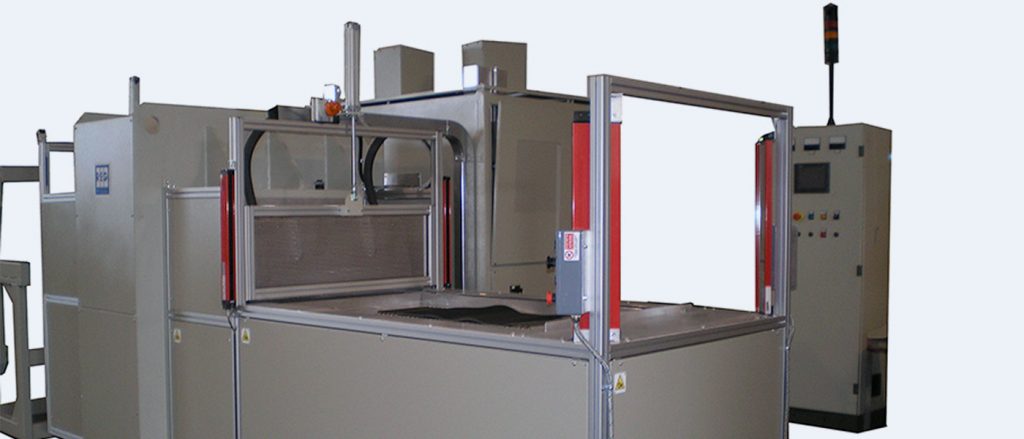

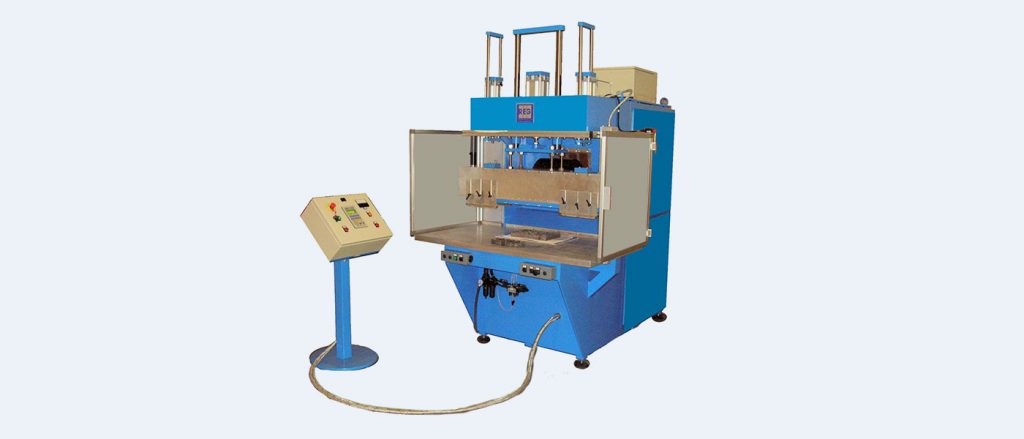

REG welding machines for automotive industries

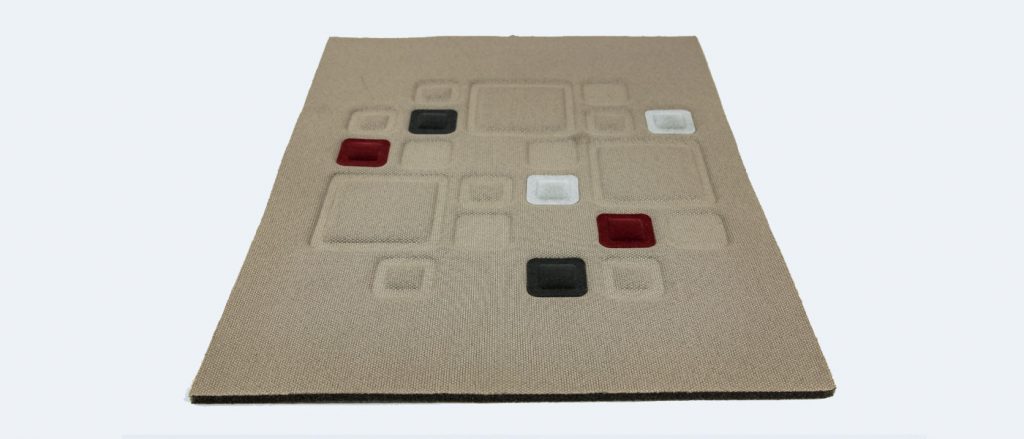

Car seat embossing HF welders : the solution for car seat manufacture that guarantees best results time after time.

Applications for Automotive sector

Car seat embossing through high frequency embossing welders is the primary method used to modify fabrics and thermoplastic materials and confer them the appearance and look desired by car interior designers. The requirements of the car seat embossing sector are simple, but exacting: absolute precision, stability of results, absence of defects in the finished product, and applicability to a wide range of different materials. Fortunately, high-frequency car embossing welders are capable of guaranteeing all of the above.

Our solution for your problem

High-frequency is considered the state-of-the-art technology for car seat embossing welders because it diffuses energy uniformly over the whole fabric, avoiding any critical spikes: this leads to consistent, homogeneous and at the same time stronger welding, allowing for perfectly identical pieces. Furthermore, welding and embossing are entirely obtained at low temperatures, which not only makes embossing clearer and more precise, but also guarantees the absence of any superficial fabric damage, allowing for designs of any kind to be obtained. The technology used in top-range machines, such as the ones REG has already provided to some of the largest manufacturers in this field, also allows for a wide range of materials to be employed. Upon request we can produce hot quilting machines.

Automotive gallery

We build and sell high frequency press custom on the customers need from 9 to 60 kw to embossing automotive textile, carpet floor welding, sun visor and all other application where high frequency technology is necessary or asked. We specialize in tissue welding.