In the world of industrial welding, choosing the right technology isn’t just a technical decision, it’s a strategic one. You have probably asked yourself: what’s the difference between a high-frequency (HF) welder and a traditional one? The answer could be the difference between an efficient production line and one full of scrap and delays.

What is high-frequency (HF) welding?

HF welding uses electromagnetic waves to heat and fuse materials from the inside, without direct surface contact. It’s ideal for thermoplastic materials such as:

- PVC

- PU

- Coated fabrics

- Multilayer technical materials

HF vs Ultrasound vs Direct heat

| Technology | Operating Principle | Advantages | Limitations |

| High Frequency | Molecular heating from within | Uniform welding, airtight sealing, great for large surfaces | Higher initial investment |

| Ultrasound | High-frequency mechanical vibrations | Fast on small parts, energy efficient | Not suitable for thick or large materials |

| Direct Heat | Heating via contact or heating elements | Low-cost, simple | Lower quality, risk of burns or deformation |

Key Advantages of HF Welding

- Perfectly uniform joints

Welds the material internally, not just on the surface. Result: strong, airtight, clean welds.

- Ideal for large or complex surfaces

Perfect for conveyor belts, inflatable tanks, technical curtains.

- No material damage

No direct contact with heated elements. No risk of scorching or deforming.

- Consistency and automation-ready

Excellent for standardized industrial processes. Easy integration into automated production lines.

When is hf welder the right choice?

Choose high-frequency welding when you want to:

- Reduce waste

- Boost production speed

- Ensure consistent and certifiable quality

- Weld thick, technical, or delicate materials

It’s a smart investment for businesses seeking long-term efficiency and reliability.

Why choose REG Galbiati?

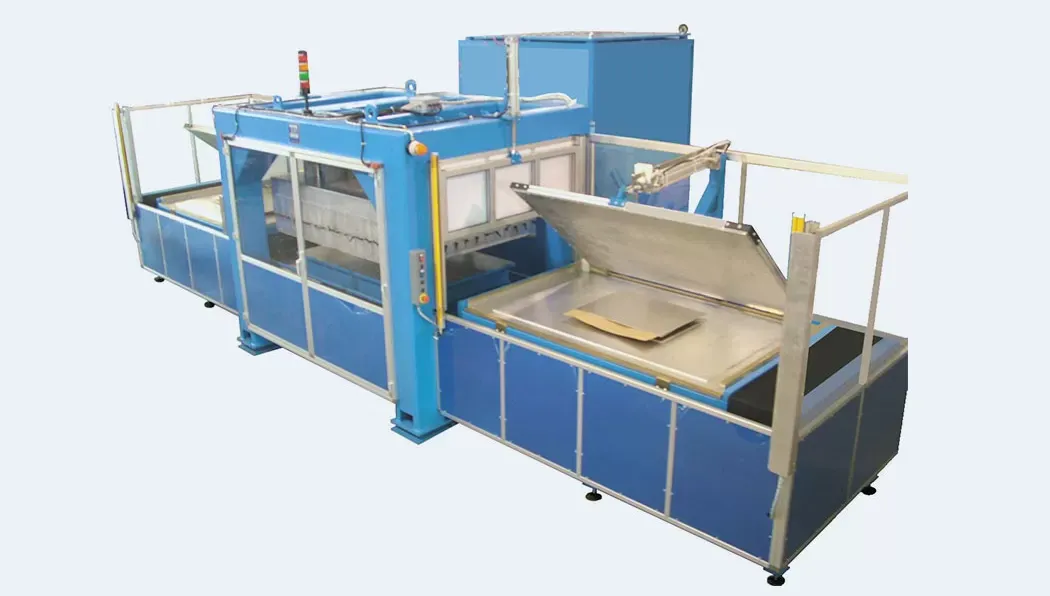

With over 70 years of experience, REG Galbiati Srl designs and manufactures custom high-frequency welding machines, tailored to your product, your workflow, and your industry.

Want to discover what a made-to-measure HF welder can do for your production?