Modern manufacturing demands versatile, efficient technologies that deliver precision without compromising sustainability or productivity. REG Galbiati srl excels in crafting custom high-frequency welding machines tailored for automotive components, conveyor belts, and packaging, empowering producers to meet diverse industry standards with superior results.

Rise of Custom High-Frequency Welding

High-frequency welding machines have evolved into essential tools for modern manufacturing, offering precise fusion of thermoplastic materials without adhesives or solvents. These systems generate electromagnetic energy to create strong, clean joints ideal for demanding applications.

Manufacturers increasingly seek these solutions to replace outdated methods, achieving higher quality and reduced environmental impact. Custom designs ensure seamless integration into existing lines, minimizing disruptions while maximizing output. This technology supports the shift toward sustainable practices by eliminating chemical waste and enabling efficient material use.

Energy Efficiency Advantages

High-frequency welding excels in energy efficiency compared to traditional heat or ultrasonic methods, as energy focuses directly within the material rather than external heating elements. REG machines optimize power usage from controlled generators, reducing overall consumption and operational costs.

The process produces no fumes or emissions, creating safer work environments and simplifying compliance. Operators benefit from shorter cycle times and lower maintenance needs due to durable components.

Tailored Solutions Across Industries

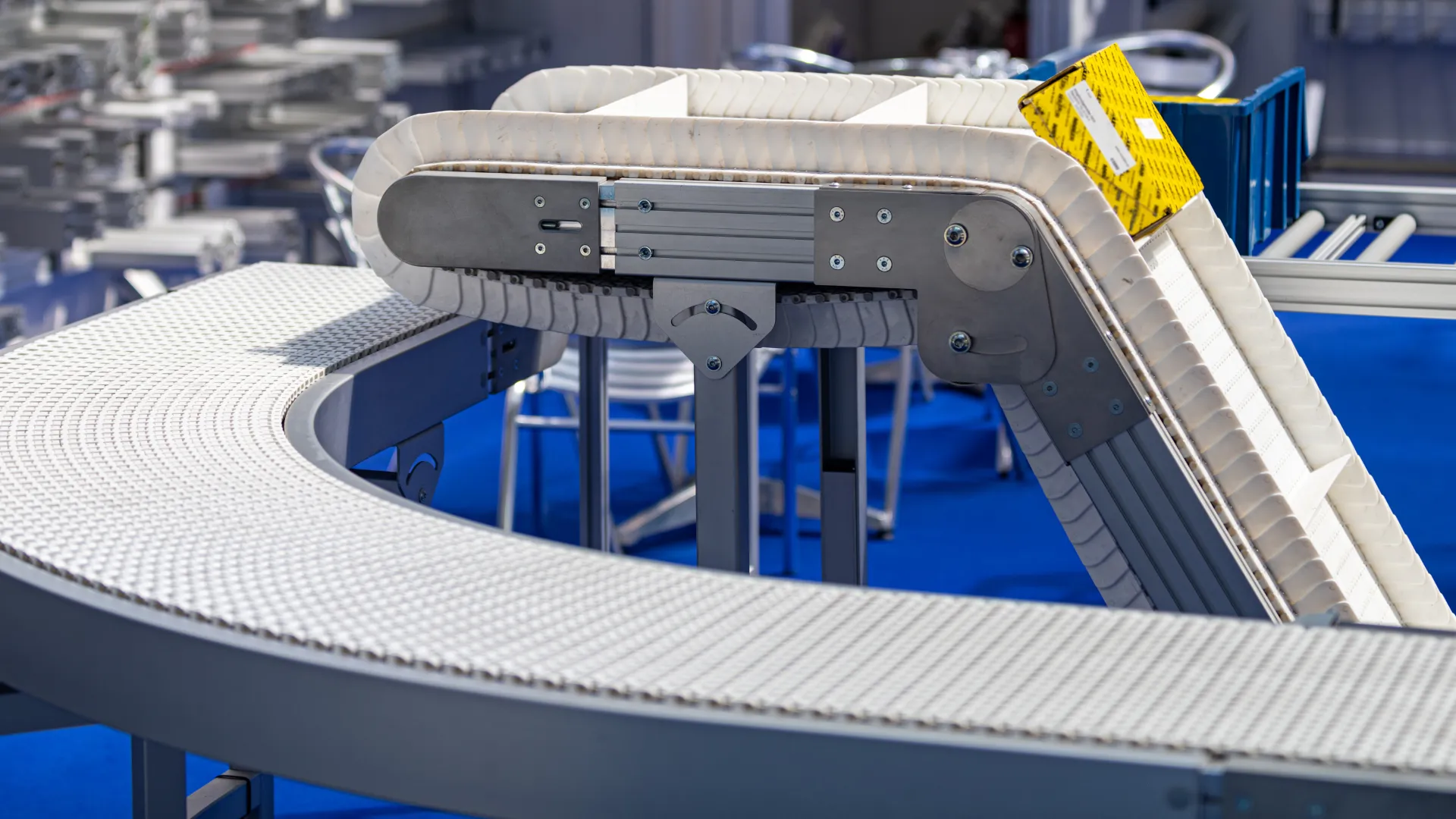

REG Galbiati designs high-frequency welding machines for diverse applications, from automotive seat covers to conveyor belt reinforcements and blister packaging. Each system features adjustable parameters for material thickness, weld patterns and production speeds. Custom tooling ensures precision on challenging substrates like PVC, PU and laminates.

In conveyor belts, machines apply robust details for industrial durability. Packaging solutions create secure, attractive blisters for non-food products. Automotive welders handle low-dielectric fabrics for premium finishes. This versatility positions REG as a one-stop partner for multi-sector manufacturers.

Why Choose REG Galbiati

REG Galbiati’s high-frequency welding machines are known for reliability and innovation in custom engineering. Their systems deliver consistent results on large batches, reducing downtime through robust construction and precise controls. Clients value the balance of performance, adaptability and long-term efficiency.

Compared to generic welders, REG solutions offer superior weld strength and repeatability, driving competitive advantages.