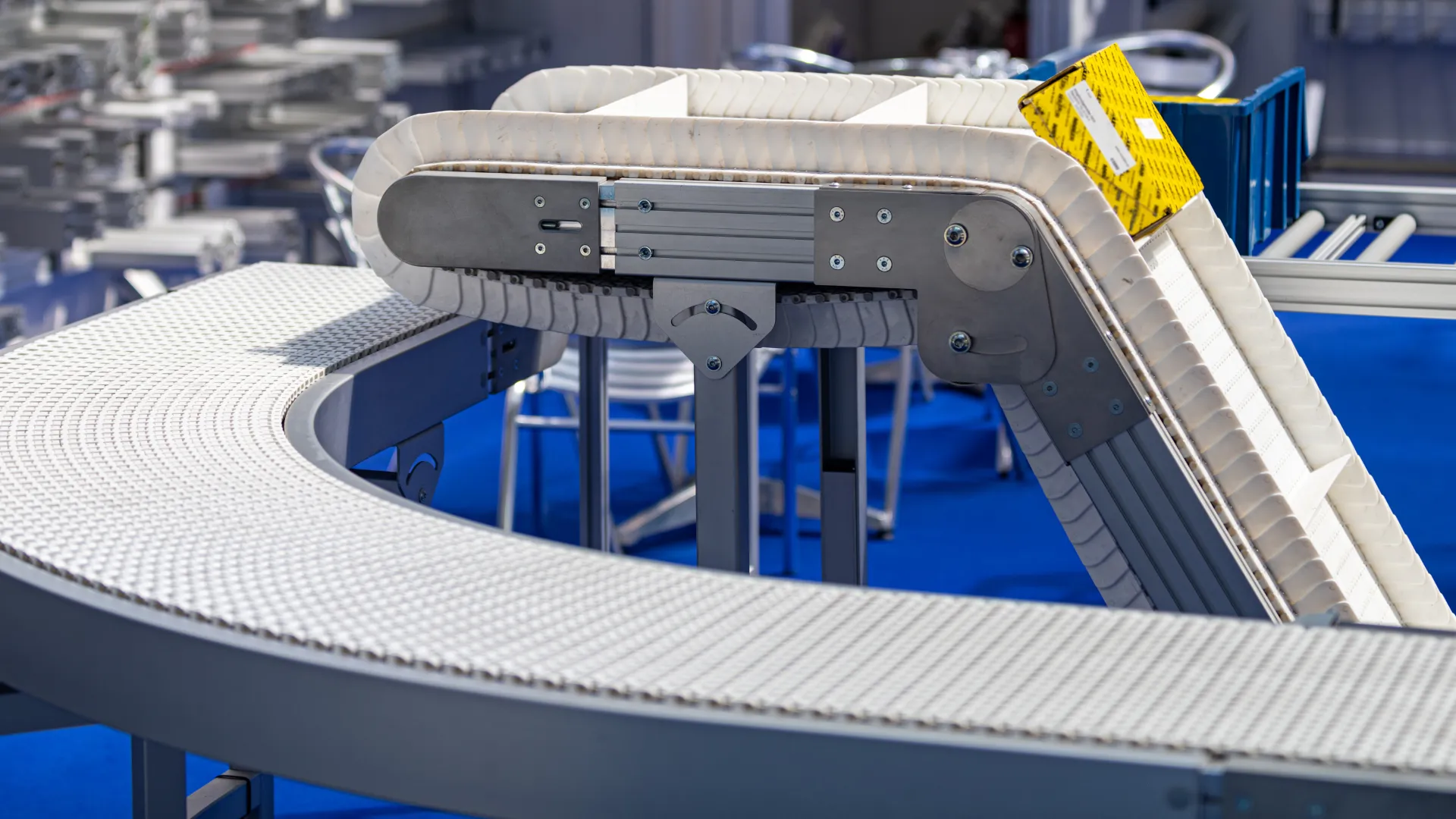

PVC conveyor belts are widely used across industries for efficient material handling. Known for their durability and flexibility, these belts cater to a variety of applications, particularly in food processing, manufacturing, and logistics.

Features and advantages

PVC conveyor belts are made with a synthetic fiber core coated with PVC plastic. This construction provides high tensile strength, minimal stretching and outstanding resistance to wear and tear.

Notable advantages include:

- Robustness: designed for light to medium loads, offering resistance against abrasion and impacts.

- Chemical resistance: can endure exposure to hot water, steam and certain chemicals.

- Temperature tolerance: Functions effectively at temperatures reaching up to 60°C.

- Antistatic Properties: prevents static electricity buildup during operation.

- Custom Design: available in different widths and thicknesses to suit various applications.

Applications of PVC conveyor belts

PVC conveyor belts are versatile and find applications across multiple industries:

- Food sector: ideal for bakery production, dairy processing, meat and fish handling, as well as fruit and vegetable transportation due to their hygienic properties.

- Manufacturing: suitable for moving raw materials, packaged goods, and lightweight items in production facilities.

- Logistics and warehousing: facilitates the efficient movement of packaged goods within distribution centers.

- Textile industry: used in machines such as blow room equipment and other textile processing systems.

REG welders for conveyor belts

Industry and automation heavily rely on the production of PVC conveyor belts; and often, the surfaces of such conveyor belts need to be equipped with specific accessories, such as sidewalls and cleats, according to specific application needs, in order to comply with industry requirements.

High-frequency transmission-based welding, such as is used in REG’s machines, proves ideal for such work because of its strength and precision. Besides this, it offers the huge advantage of being executed at low temperatures, which ensures absence of any undesired warping on projects and applications of any size and shape.

We build and sell high frequency welding machine from 3.5 to 20 kw, standard or custom to weld profile sidewall, splicing and all other application where high frequency technology is necessary. All our press respect the highest safety standard and electromagnetic field emission.

For more information about our solutions and services, please feel free to contact us.