Struggling with glue messes and slow stitching on your plastic assembly line? High-frequency welding offers a simple upgrade: fuse PVC and PU in seconds with clean, unbreakable seals. Say goodbye to adhesives and waste—hello to reliable production that scales with your business. Discover how this technology transforms manufacturing efficiency across industries.

Why Upgrade to High-Frequency Welding

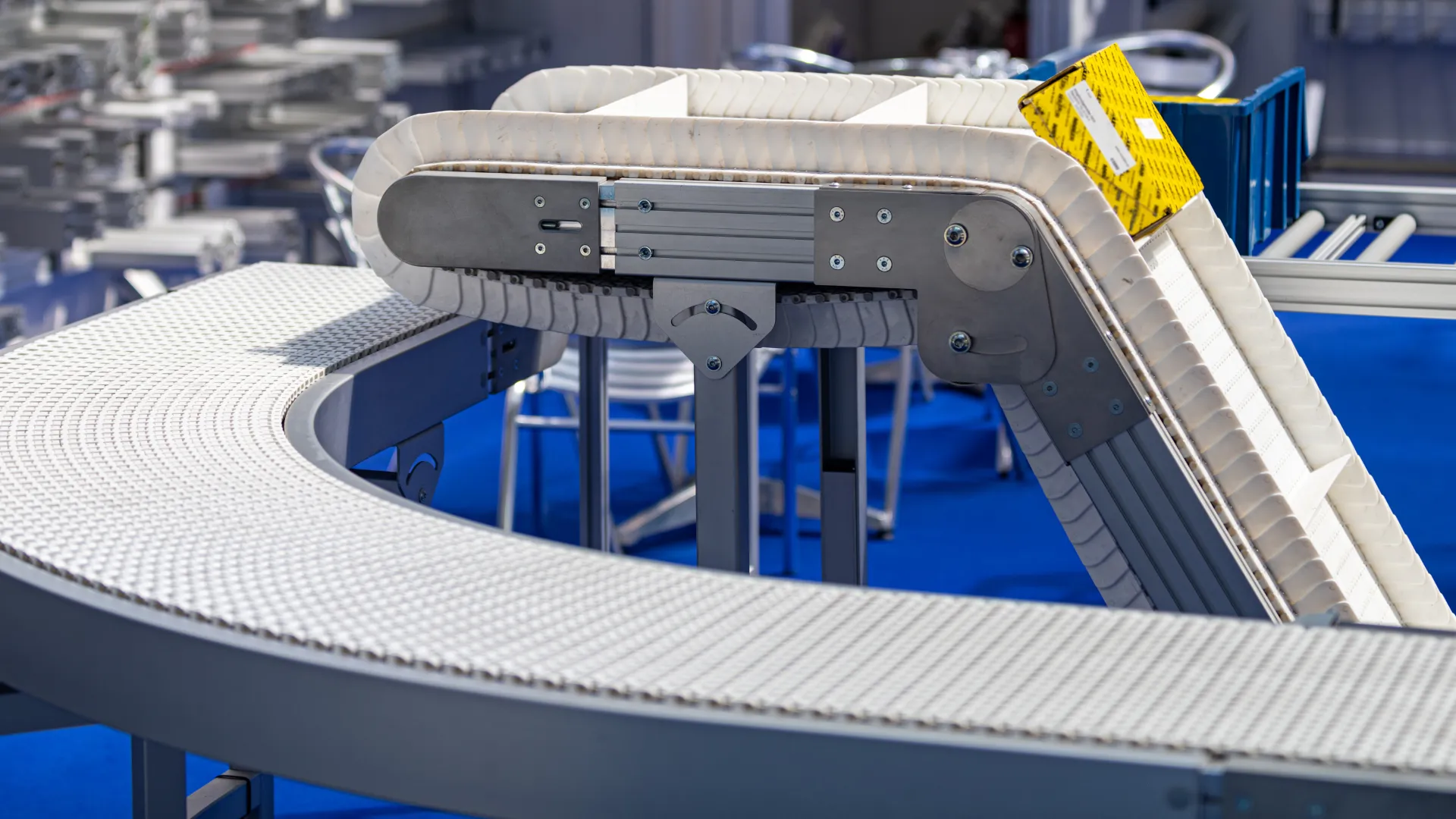

Manufacturers often face the same challenges: glue that doesn’t hold, stitching that frays, and processes that slow down production. High-frequency welding offers a straightforward solution by fusing plastics like PVC and PU directly using electromagnetic energy. No mess, no chemicals, just strong, clean seals ready in seconds. This upgrade transforms assembly lines handling packaging, conveyor belts or protective covers into faster, more reliable operations.

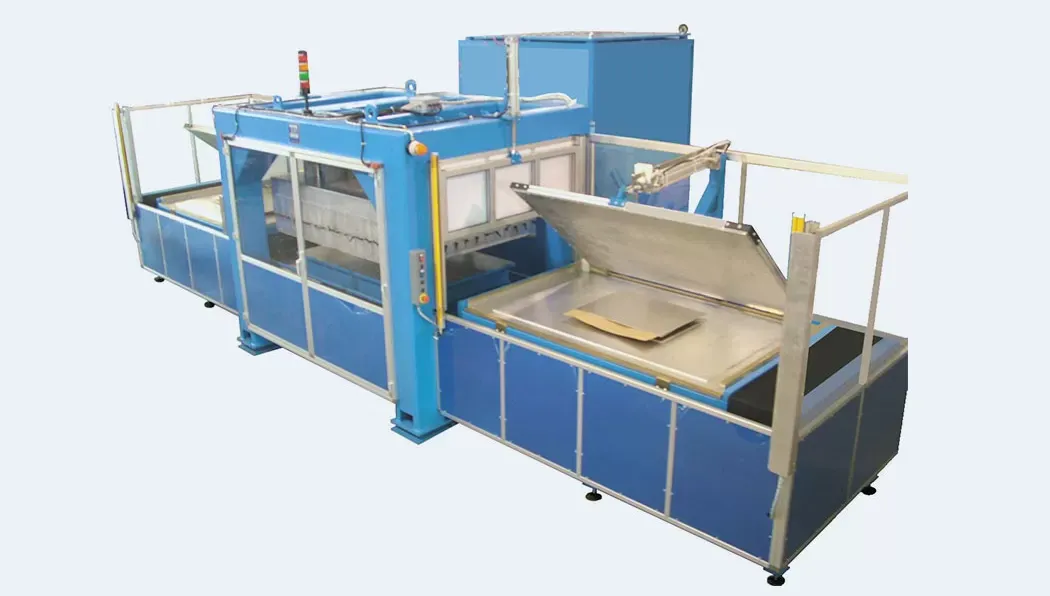

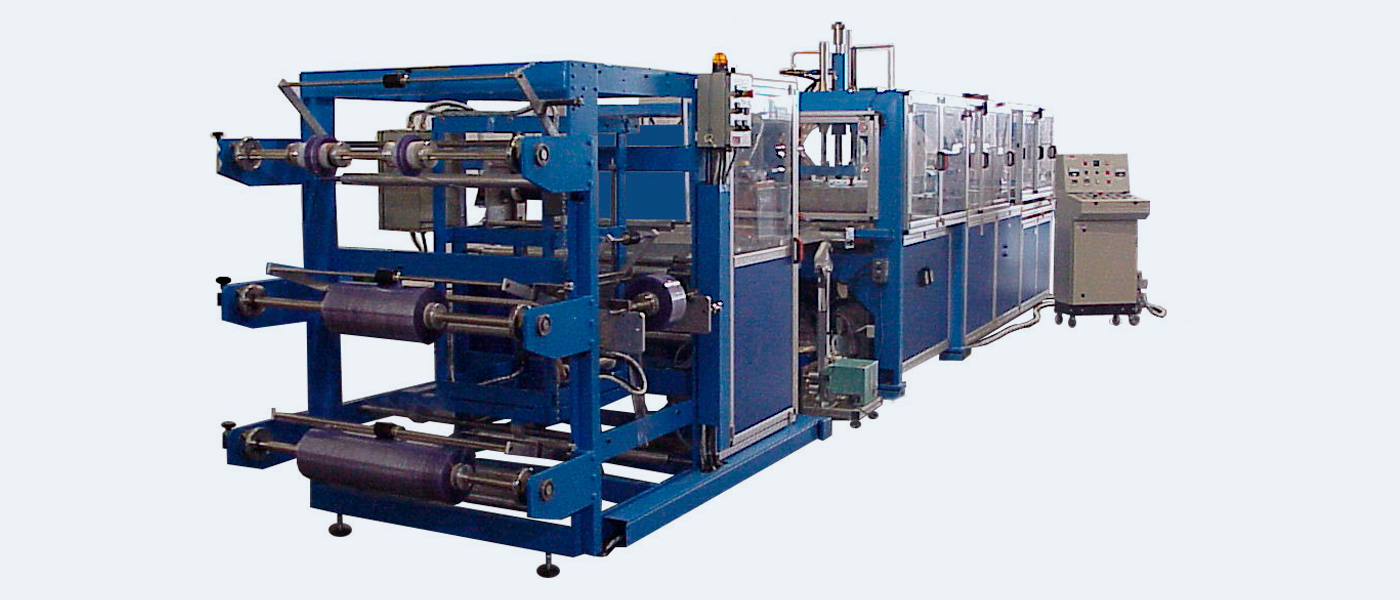

Companies switching to high-frequency welding report smoother workflows and happier operators who spend less time fixing mistakes. REG Galbiati builds machines that make this transition painless.

Simple Process, Big Results

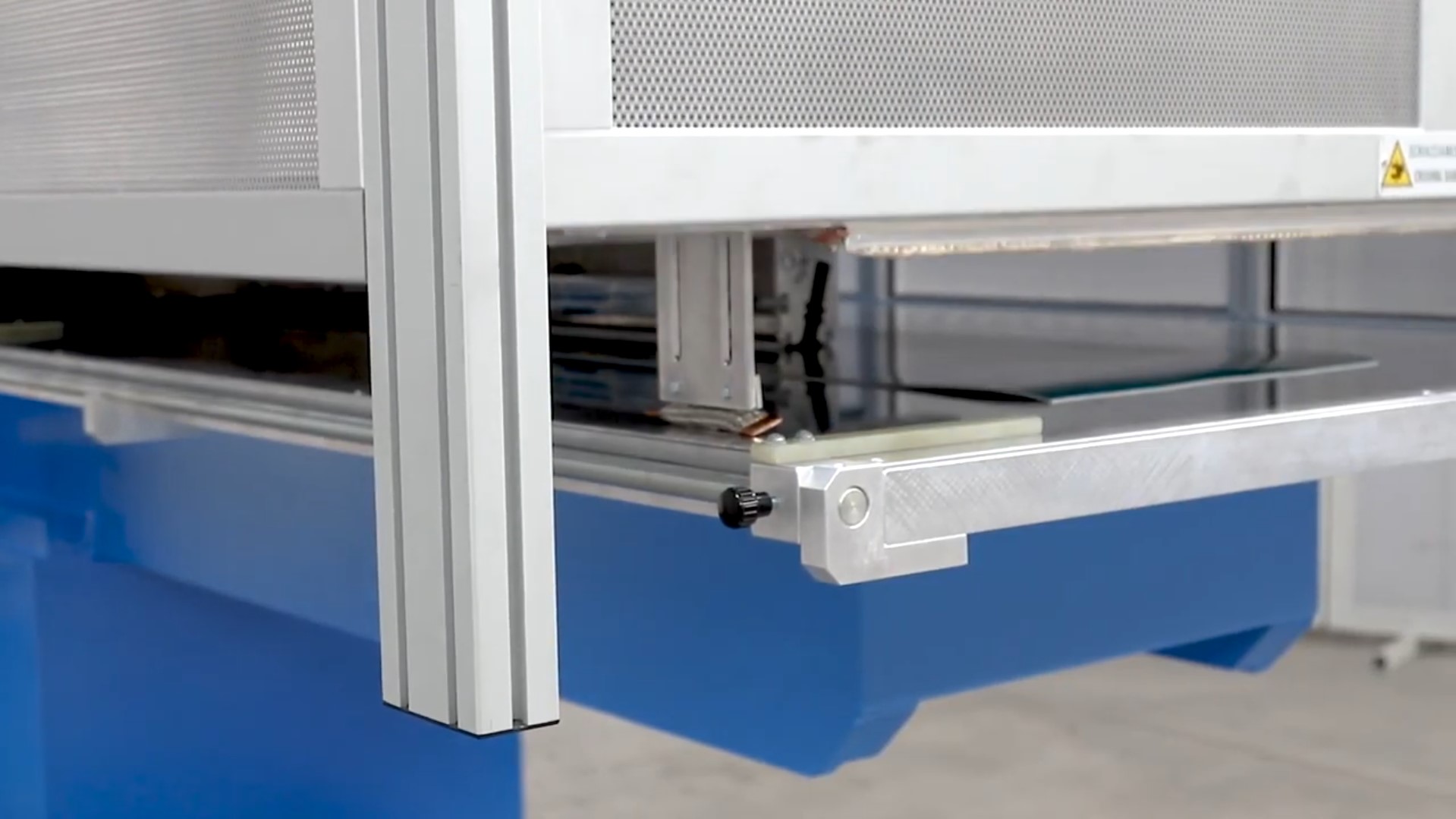

REG Galbiati equipment stands out with adjustable power levels that adapt to different thicknesses, ensuring seals work on everything from thin films to heavy-duty laminates. The result? Joints as strong as the base material, flexible enough to bend without breaking. Manufacturers value this reliability, especially when scaling from prototypes to full runs. No more weak spots or rework that eats into profits.

Cost Savings Manufacturers Love

Switching to high-frequency welding delivers quick financial wins. Energy use drops because power targets only the weld area, not the whole machine. Cycle times shrink, doubling output on the same floor space. Waste plummets—no dried adhesive or scrap from failed bonds. Facilities keep cleaner too, cutting cleaning crew hours.

REG Galbiati machines pay back investment through everyday efficiency, making them practical for small runs or high-volume lines alike.

Perfect Fit for Your Industry

High-frequency welding fits seamlessly across manufacturing. Packaging firms seal pouches airtight for longer shelf life. Logistics companies reinforce conveyor belts for heavier loads. Automotive suppliers bond protective covers that endure weather and wear.

REG Galbiati supports this versatility with machines built for real-world demands.

How to Make the Switch

High-frequency welding isn’t futuristic tech; it’s the practical next step for manufacturers ready to work smarter.

Reach out to REG Galbiati and simplify your plastic assembly today.